Display Mode | Digital Display | |||||

Model | WES-300B | WES-300D | WES-600B | WES-600D | WES-1000B | WES-1000D |

Structure | 2 Columns 2 Screws | 4 Columns 2 Screws | 2 Columns 2 Screws | 4 Columns 2 Screws | 2 Columns 2 Screws | 4 Columns 2 Screws |

Max.Load Force | 300kn | 300kn | 600kn | 600kn | 1000kn | 1000kn |

Test Range | 2%-100%FS | |||||

Displacement Resolution(mm) | 0.01 | |||||

Clamping Method | Manual clamping or Hydraulic clamping | |||||

Piston Stroke(Customizable) | 150mm | 150mm | 200mm | |||

Tensile Space | 550mm | 550mm | 600mm | |||

Compression Space | 500mm | 500mm | 550mm | |||

Round Specimen Clamping Range(mm) | 4-10 (10-20,20-32 optional) | |||||

Flat Specimen Clamping Range(mm) | 0-15 | 0-15(15-30 optional) | ||||

Compression Plate(mm) | φ150 | Φ200 | ||||

Display Mode | Microcomputer Display | |||||

Model | WEW-300B | WEW-300D | WEW-600B | WEW-600D | WEW-1000B | WEW-1000D |

Structure | 2 Columns 2 Screws | 4 Columns 2 Screws | 2 Columns 2 Screws | 4 Columns 2 Screws | 2 Columns 2 Screws | 4 Columns 2 Screws |

Max.Load Force | 300kn | 300kn | 600kn | 600kn | 1000kn | 1000kn |

Test Range | 2%-100%FS | |||||

Displacement Resolution(mm) | 0.01 | |||||

Clamping Method | Manual clamping or Hydraulic clamping | |||||

Piston Stroke(Customizable)(mm) | 150 | 150 | 200 | |||

Tensile Space(mm) | 550 | 550 | 600 | |||

Compression Space(mm) | 500 | 500 | 550 | |||

Round Specimen Clamping Range(mm) | 4-10 (10-20,20-32 optional) | |||||

Flat Specimen Clamping Range(mm) | 0-15 | 0-15(15-30 optional) | ||||

Compression Plate(mm) | φ150 | Φ200 | ||||

Display Mode | Full Computer Control and Display | |||||

Model | WAW-300B | WAW-300D | WAW-600B | WAW-600D | WAW-1000B | WAW-1000D |

Structure | 2 Columns 2 Screws | 4 Columns 2 Screws | 2 Columns 2 Screws | 4 Columns 2 Screws | 2 Columns 2 Screws | 4 Columns 2 Screws |

Max.Load Force | 300kn | 300kn | 600kn | 600kn | 1000kn | 1000kn |

Test Range | 2%-100%FS | |||||

Displacement Resolution(mm) | 0.01 | |||||

Clamping Method | Manual clamping or Hydraulic clamping | |||||

Piston Stroke(Customizable)(mm) | 150 | 150 | 200 | |||

Tensile Space(mm) | 550 | 550 | 600 | |||

Compression Space(mm) | 500 | 500 | 550 | |||

Round Specimen Clamping Range(mm) | 4-10 (10-20,20-32 optional) | |||||

Flat Specimen Clamping Range(mm) | 0-15 | 0-15(15-30 optional) | ||||

Compression Plate(mm) | φ150 | Φ200 | ||||

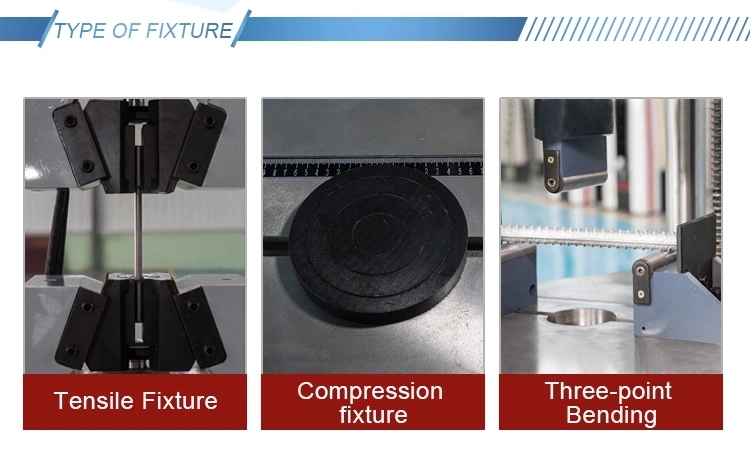

The differences of the above three universal testing machines: 1.Digital display, screen display, microcomputer servo control of the three universal testing machine host is the same, the difference lies in the control system and display. Digital display is the simplest one: display by the single-chip display, printing thermal paper strip, automatic display test force value.Clamping mode is automatic clamping, manual oil feeding and oil return control. 2.The screen display is semi-automatic equipment, the display mode is computer display, printing A4 report, adding test standards, adding extensiometer, clamping mode automatic clamping, manual oil supply and return control. 3.The microcomputer servo control is a fully automatic device, which can automatically collect and calculate the output experimental results in the whole process. It can realize force maintenance and force loading experiments, and has the functions of automatic oil feeding and oil returning.

FAQ

1. Are you a manufacturer?

Yes, we are professional manufacturer of every kinds of testing machines in China. In general, every machine shipped from our factory provides 12 months of free maintenance, taking into account shipping reasons. We can extend the maintenance period for our customers for 2 months.

2. Do you have after-sales service? How can I ask? What about warranty?

Before the delivery of the equipment, we will carry out the factory inspection and the equipment will be shipped after the inspection. If your machine does not work properly, you can contact us and we will try our best to communicate with you via email or skype video chat. We promise we will reply to you within 24 hours and with 3 Within a working day to provide solutions. After confirming that it is really necessary, we can send you new parts or on-site maintenance.

The service does not include mechanical failure due to the following reasons:

(1) Wrong operation;

(2) Privately modified;

(3) Failure caused by non-equipment itself

(4) Use environment that is not suitable for equipment operation. Such as high temperature, humidity, corrosive gas or vibration.

(5) Problems caused by movement or transportation.

(6) Consumable components.

(7) Natural disasters

3. What is the delivery deadline?

Most of the time, we have inventory at the factory. If not, the delivery time is usually 15 to 20 days after receiving the payment. If you need it urgently, we can consider making special arrangements for you.

4. What kind of packaging and transportation do you use?

Under normal circumstances, we will use ordinary orders such as DHL, Fedex, UPS TNT transport. Large orders will use aviation or shipping.

5. Can the device be customized? Can I customize my own design on the device?

We can not only provide standard machines, but we can also provide customized machines according to your needs.

At the same time, we can also place your trademark on the machine.

6. What kind of packaging do you use?

Plastic sealed and sturdy wooden box.

7. What payment methods do you support?

Paypal, T/T, Western Union,L/C