Technical Specifications

| CPU | Main parameter of electrical source | ||||

I/O | 14-CH 24VDC input 10-CH Relay output | Supply Voltage | 220VAC @50Hz | ||

| Expansion capability | Up to 10 modules can be extended | Allowance range | 187~264VAC @50Hz | ||

| Storage capacity | Program area : 120KB | Maximum current | 120mA | ||

| N Area : 8KB M Area : 5KB | Output Voltage | 24VDC | |||

| Power loss holding area : 2KB | Output Current | 400mA | |||

| Timer | Hardware timing : 1, 0.1ms ~ 500ms No limit on software timing (min. 1ms) | Short-circuit protection | 800mA,24VDC output | ||

| Counter | 16bit | Communication interface | 1*RS232, | ||

| Operating rate | 0.06μ s(Boolean operation instruction) | 1*RS485 | |||

| Interrupt input | 4 | Communication protocol | MODBUS RTU protocol, | ||

| Analog potentiometer | 2 ,0~255 | Custom protocol | |||

| Input Channal | Output Channal | ||||

| Type of input | P/M-lesend | Type of output | Relay | ||

| Input signal | Rated voltage 24VDC | Output signal | Rated voltage 24VDC or 24 ~ 230VAC | ||

| 0 ~ 30V DC | 5 ~30VDC or 5 ~ 250VDC | ||||

| Input signal (ON) | 15~30VDC and > 3 mA | Common terminal output current summation | < 5A | ||

| Input signal (OFF) | 0~5VDC and < 1mA | Output contact capacity | 2A, Impedance load | ||

| Input delay | < 0.6ms (Rated input voltage) | Switch delay | < 10ms | ||

| Isolation method | Optoelectronic isolation | The isolation voltage between the coil and the contact | 3000V AC, 1min, leak current 1mA | ||

| Isolation of pressure | 1000VDC | Isolation voltage between contacts | 750V AC, 1min, leak current 1mA | ||

| Mechanical life of relay | Without load, it can reach more than 10,000,000 times; Rated resistance 2A load, up to more than 100,000 times | ||||

| Dimensions and Mounting | Work Environment | ||||

| Dimensions | 120mm(L)×80mm(W)×63mm(H) | Operating temperature | 0 ~ +55ºC | ||

| Weight | 380g | Storage temperature | -40 ~ +70ºC | ||

| Way to install | 35mm DIN rail | Relative humnidity | 5% ~ 95% Noncondensing | ||

| Panel mounting type | |||||

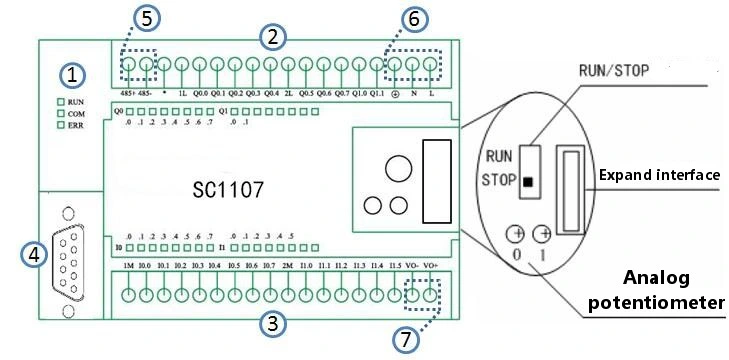

Main interface and terminal definitions

1.Indicator lights: RUN, COM and ERR are used to display module operation, communication and fault conditions respectively, I and Q are used to show the module operation, communication and fault conditions respectively. Indicates the input and output status of each channel.

2.Module output terminal: It is composed of power supply driver 1L, 2L and output point Q. "*" indicates that there is no actual output on this channel. Physical connection, with relay output at the terminal.

3. Module input terminals: consisting of common terminal 1M, 2M and input point I. Source/drain type connection can be used.

4. RS232 communication interface: This interface can be used for program download, communication with touch screen and host computer. MODBUS RTU/free protocol.

5. RS485 communication interface: This interface can be used to communicate with touch screen, upper computer, third-party instruments, etc., and supports MODBUS RTU/free protocol.

6. Power supply of the module: L, N, GND AC220V power supply's fire wire, zero wire and protective ground terminal.

(vii) 24VDC power supply external to the module: VO+ and VO- are 24VDC positive and negative terminal blocks respectively.

Note: PCS1200 programmable logic controller terminals are all pluggable.

Terminal tag definition specification

| Terminal | Terminal instructions | Terminal | Terminal instructions |

| 485+ | The positive pole of the RS485 interface | 1M | External input common terminal |

485- | The negative pole of the RS485 interface | I0.0 | Normal input terminal |

| * | Undefined | I0.1 | Normal input terminal |

| 1L | Output common | I0.2 | Normal input terminal |

Q0.0 | Normal Output terminal | I0.3 | Normal input terminal |

Q0.1 | Normal Output terminal | I0.4 | Normal input terminal/External interrupt input |

Q0.2 | Normal Output terminal | I0.5 | Normal input terminal/External interrupt input |

Q0.3 | Normal Output terminal | I0.6 | Normal input terminal/External interrupt input |

| Q0.4 | Normal Output terminal | I0.7 | Normal input terminal/External interrupt input |

2L | Output common | 2M | External input common terminal |

Q0.5 | Normal Output terminal | I1.0 | Normal input terminal |

Q0.6 | Normal Output terminal | I1.1 | Normal input terminal |

Q0.7 | Normal Output terminal | I1.2 | Normal input terminal |

Q1.0 | Normal Output terminal | I1.3 | Normal input terminal |

Q1.1 | Normal Output terminal | I1.4 | Normal input terminal |

| GND | RS232 ground terminal | I1.5 | Normal input terminal |

N | Zero line | VO- | External power supply :positive |

L | Fire line | VO+ | External power supply :negative |

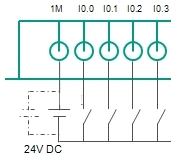

Input channel connection mode

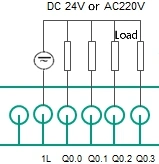

Output channel connection mode

RS232 communication port definition

| PIN | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

| Definition | -- | RXD | TXD | -- | GND | -- | user-defined | user-defined | -- |

About CHINT

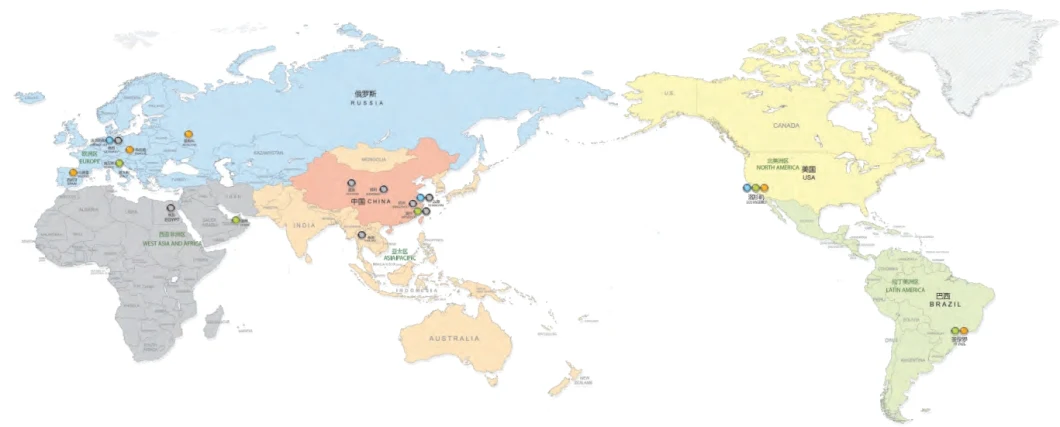

Founded in 1984, the Chint Group provides safe, reliable and stable industrial electrical equipment and solutions for energy efficient management systems. With 30 years of development it has grown to be Asia' s largest low*voltage electrical product supplier and is the leading brand of the whole industry chain in industrial electric in Asia. With three R&D centers located in Europe, North America and China, there are also branches in over 20 countries and more than 30.000 employees in the world. CHINT provides reliable products, system solutions and services to more than 100 countries worldwide.

• 3 Global Research Centers: Europe, North America, Asia Pacific

• 6 International Marketing & Sales Area: Asia Pacific, Middle East and Africa, Europe, Latin America, North America, China

• 9 Manufacturing Bases: China (Wenzhou, Shanghai, Hangzhou, Jiaxing, Xianyang, Jiuquan), Thailand, Egypt, Germany

• 22 Logistics Centers 14 International Subsidiaries 17 Marketing Offices in China 2300 Sales Companies

About Chitic

Chrtic Control Engineering Co.. Ltd. is a subsidiary company of Chint, and a leading provider of automation & control technologies and applications in China that helps the industry customers to improve operating safety, reliability and efficiency. Chitic has series of products including PCS1800 DCS, TDCS9200 DCS and CTS700 DCS, information platform for water company, control system for high speed rapier loom, drive system of switched reluctance motor, solar energy monitoring system, computing cloud center for new energy; etc. Chitic control system won 2006 National Science and Technology Progress Awards of China, CTS700 DCS won the award of 2010 Innovative Product of China. Chitic headquarter is located at the beautiful city of Hangzhou, two hours drive from Shanghai. Chitic has its own science & technology park, Chitic Park, which covers about six thousand square meters.

Our Business Sector

Typical Reference